The best printing techniques for corporate gifts

When investing in a corporate gift or promotional product, thinking about the proper printing technique is paramount to communicating your logo or message in the best possible way. Leoprinting offers numerous printing options. Below, we list the pros and cons of the various printing techniques to ensure your logo or advertising message stands out positively.

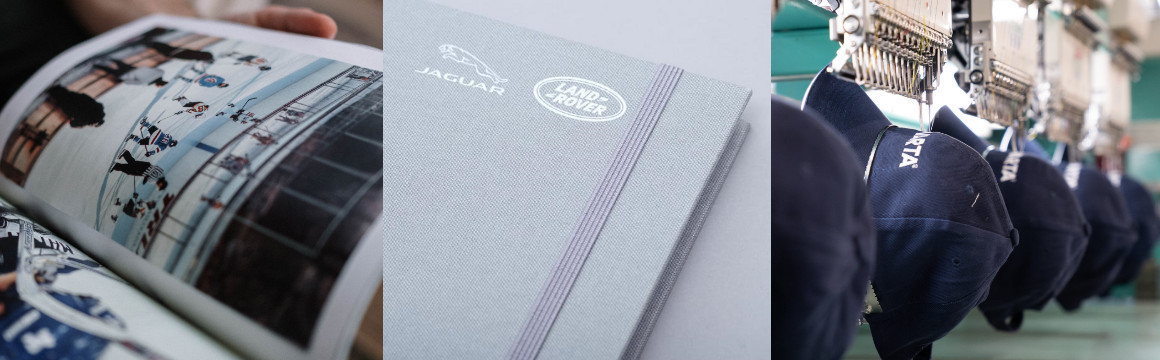

Offset printing

Offset printing is the most commonly used printing technique for printing paper corporate gifts in extensive runs because of its high accuracy and quality. Offset printing is also a cost-effective solution for high-volume printing. In this printing method, the design of a plate is printed on a rubber blanket and then applied to the printing surface. The technique is widely used for printing large runs of paper, such as sticky notes, business cards, flyers, calendars, the contents of (note)books, magazines, as well as mouse pads. Due to the high set-up costs, this printing technique for promotional gifts is less suitable for small print runs.

Image: offset printing

Digital printing

Digital printing is similar to printing with an office printer, but on a large scale. It involves printing directly from a digital file, such as a PDF, without needing a physical printing plate. This makes this printing technique a faster and more flexible printing option than offset printing, for example. For example, there is the possibility of making quick changes to the printed material at no extra cost. Moreover, digital printing can produce high-quality prints with bright, vibrant colours and fine details. It is also an eco-friendly option, as this printing technique for corporate gifts uses less ink and energy than traditional printing methods. Digital printing is widely used for lower print runs; think of products such as speakers, gadgets, playing cards, and water bottles.

Image: digital printing

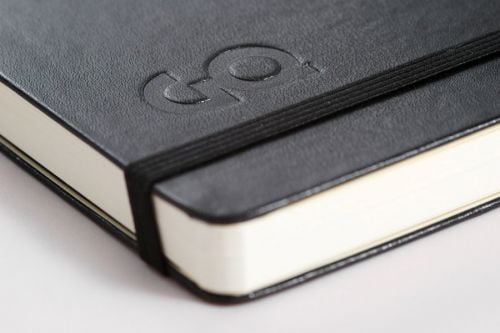

Debossing

Debossing is a technical term referring to gravure printing. Here, a heat stamp is printed into paper, cardboard, or imitation leather, creating a lowered 3D effect (or a raised 3D effect, which is called embossing). This printing technique is called ‘debossing’ because no ink or foil is involved, and the design remains the same colour as the material it is printed on. One of the main advantages of debossing is that the technique adds a unique and tangible element to the printed product. Promotional gifts are thus given a luxurious look, and the printing stands out subtly. However, the technique can be more expensive than other printing techniques because it requires a separate embossing (stamp). Moreover, debossing is unsuitable for printing large areas or especially highly detailed designs, as the raised or lowered effect can make these elements hard to see. Debossing can be combined with other printing techniques for promotional gifts, such as foil printing.

Image: debossing

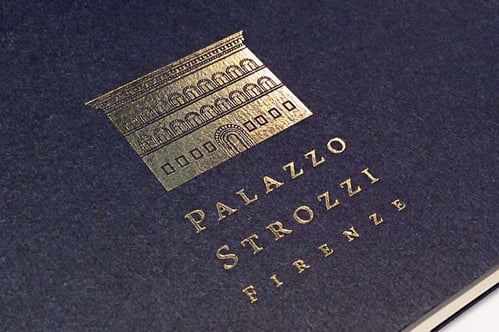

Foil printing

Foil printing is a promotional gift printing technique in which foil, such as metallic, is applied to the material using heat and pressure. It is a popular choice for giving printed materials a luxurious, glossy look. Foil printing is also a durable printing method, as the foil is applied with heat and pressure, making it less prone to scratches or stains. Foil printing can be used in one colour of your choice, but is unsuitable for printing detailed or very small designs. The technique can also be used in combination with, for example, debossing.

Image: foil printing

Debossing with transparent foil layer

In addition to common debossing, this printing technique applies a transparent film layer of, for example, PET or PVC for an extra luxurious look. The film is applied over the embossed design, creating a raised or lowered 3D effect with a glossy or matt finish. Leoprinting deploys this printing technique particularly for luxury packaging. Not only does this technique for promotional gifts add a unique, tactile element to the design, but the foil also has a protective effect.

Image: debossing with transparent film layer

Screen printing

Screen printing is a printing technique in which PMS colours are printed in ink through a screen onto a printing surface. It is a popular choice for printing already-produced promotional gifts, such as notebooks, bags, umbrellas, and t-shirts. Screen printing is a cost-effective and durable printing technique for promotional gifts, as the ink is applied directly to the printing surface, making it less prone to fading or scratching. However, it is not possible to print very fine details or smooth colour transitions with screen printing.

Image: screen printing

Transfer printing

A printing technique for printing textiles and clothing. Transfer printing is a printing method in which a design is printed on transfer paper or foil, which is then applied to a material such as textiles. The advantage of transfer printing is that the dye penetrates deep into the fibre in this process, allowing vibrant colours, fine details, and colour transitions to be printed on irregular surfaces. Transfer printing is a more labour-intensive process than screen printing, for example, which is printed directly onto the surface. While this printing technique for corporate gifts and business promotion is more expensive than screen printing, it offers more possibilities in terms of colour use, among other things.

Image: transfer printing

Embroidery

Embroidery is a classic technique in which a design or pattern is stitched onto a fabric with thread. It is a popular choice for embroidering corporate clothing, bags, towels, and even notebooks. The main advantage of embroidery is that it gives a professional, high-quality, and lasting look to textile products. The design will not fade or wash away. However, embroidery can be a time-consuming and labour-intensive process.

Tampon printing

Tampon printing can transfer a 2D image to a 3D object using a flexible printing plate and ink and is, therefore, especially suitable for round surfaces, such as pens. The technique is most similar to stamping. It is called tampon printing because a silicone pad is used to transfer the design onto the object. This printing technique for promotional gifts is very precise and can produce detailed prints with detailed colour transitions. Leoprinting uses tampon printing for corporate gifts, including pens, coffee mugs, water bottles, and standard notebooks. The main difference with screen printing is that screen printing uses PMS colours, while tampon printing uses standard colours and often cannot always achieve companies' brand identity colours.

Image: tampon printing

Lasering

Lasering is a modern method of traditional engraving and a must in the list of the most commonly used printing techniques for corporate gifts. It involves using a laser to apply ink or toner to a surface. One of the main advantages of laser printing is that it produces very sharp, clear prints quickly and efficiently. This makes lasering suitable for printing large quantities of documents or materials. On the downside, the technique only allows for a limited number of colours to be used. Leoprinting uses lasering to personalise metal promotional gifts, such as products made of aluminium and stainless steel.

-jpg.jpeg?width=499&height=333&name=Persoonsnamen_900x600-High-Quality%20(1)-jpg.jpeg)

Image: lasering

Find the best printing technique for your corporate gifts

Whether you are looking for unique, high-quality printing or a quick solution to personalise corporate gifts, Leoprinting is the place to be. We will gladly assist you in finding the best solution to bring your logo or message to life. Are you looking for tailor-made advice on the best printing technique for your corporate gift? Then don't hesitate to contact one of our specialists. We will gladly inform you about the most commonly used printing techniques! For a result worth being seen.

English

English Nederlands

Nederlands Deutsch

Deutsch Belgium

Belgium Français

Français Español

Español